Our company has a single development room and deep cooperation with suppliers. During the development period, we have entered quality requirements to ensure that the raw material quality is developed to be qualified

Our company has CNAS laboratory to provide escort for incoming material inspection

Based on the operation of GMP and ISO9001 systems, MES system implements production process control and material control

Production material preparation process, bidirectional scanning of codes, error prevention measures to prevent material omission, wrong addition, over addition, and under addition

The traceability system is complete, and the entire process of product traceability, material traceability, and production process traceability can be traced

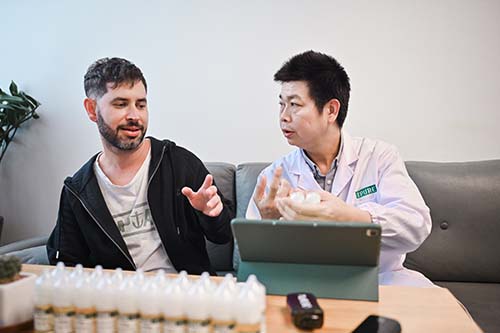

We attach great importance to customer feedback and suggestions, and have established the "Customer Complaint or Feedback Control Procedure" and "Customer Satisfaction Measurement Control Procedure" to timely collect and process customer feedback information, ensure customer satisfaction and loyalty, and establish a good corporate image

There are 50 people, 2 with PhD, 6 with Master, 28 with Bachelor, 12 with more than 5 years of work experience, 10 with 2-4 years of work experience

Equipped with 100 sets of precision testing equipment such as GC-MS/GC-FID/HPLC/densitometer/viscometer/refractometer, etc., to meet the test of more than 50 items such as component analysis, nicotine, propylene glycol, glycerol, carbonyl compounds, release, density, viscosity, refraction, etc.; It covers an area of 500 square meters and has physical and chemical analysis room, balance room, instrument room, sample retention room, etc.;